If you are a SAP Manufacturer of discrete products, today’s volatile supply chain environment has caused a huge increase in costs, reduced customer satisfaction, and a backlog of orders. As the service team gets bombarded with customer inquiries on the status of orders, sales teams struggling to get new orders with estimated timelines, Manufacturers are wondering what they can do now with the current technology stack to salvage their business. The biggest problem that manufacturers have, especially SAP manufacturers, is the disparity between your CRM and your ERP system. As a CRM/IT leader, you have some options which you can use to pull your business out of the current crisis mode and offer the Sales and Service team some level of comfort and confidence. So here are the 2 options which you can use at your disposal and focus your team on it.

Reduce Pricing Errors with Quick Integration and Controls

Most of the manufacturers leverage pricing applications that involve dynamic pricing and complicated pricing rules which run on legacy applications outside of their CRM. Many of them use SAP with a heavily customized pricing engine built with a lot of custom code. Every pricing request is captured in Salesforce through integration or manual entry and executes a complicated approval process with layers of approval to approve the pricing requests. One of the challenges with a dynamic pricing environment is that it changes every day to approve prices daily which is done manually by humans with complicated pricing charts and excel templates. What if a customer gets a price quote with a price and once he approves, the sales teams get back to them at a different price which really makes the customer mad? Simple errors done by pricing teams due to lack of current pricing data, manual processes can result in extreme customer frustrations and lead to attrition as well.

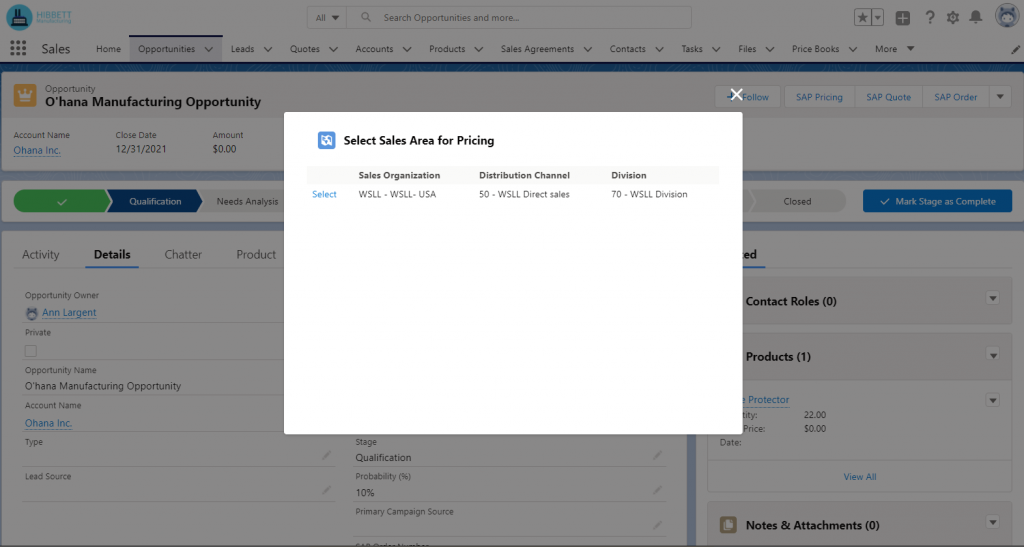

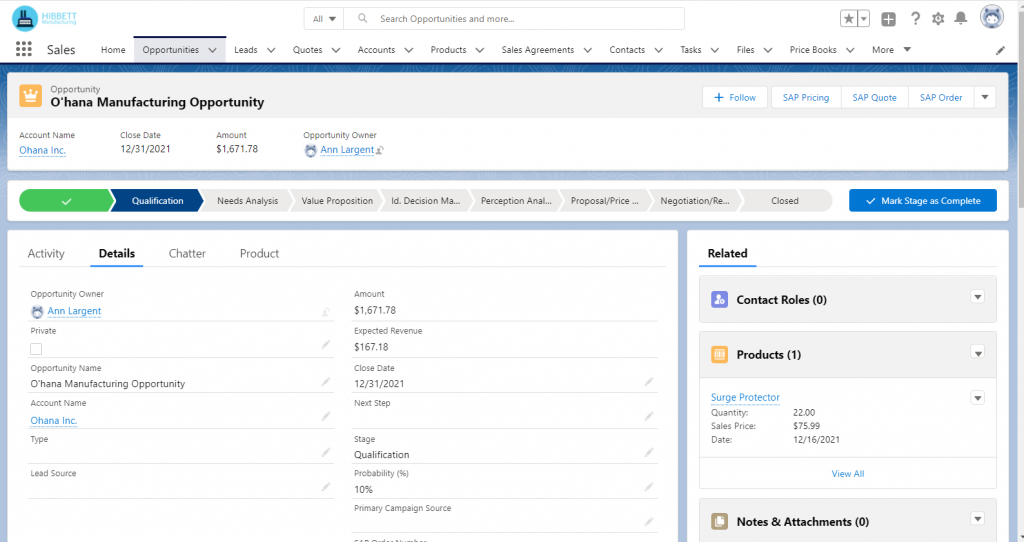

So, the solution is to apply a dynamic control mechanism that can help to flag pricing requests in your CRM system that deviate from the standard pricing rules. This is where a solution like enosix will help to validate pricing requests in real-time. Here is how the process more specifically works leveraging enosix‘s data virtualization solution. An Opportunity or quote is created, and enosix leverages the real-time SAP pricing conditions for the quoted products, including customer negotiated pricing and other complex pricing calculations, from within SAP. This pricing is then saved to the quote, and then the appropriate Salesforce workflow for approvals or applying discounts can continue. enosix ensures 100% accurate pricing throughout the process, eliminating errors and reducing manual processes. The below screenshots will provide an example of how the pricing is synced real-time leveraging enosix Salesforce integration.

Transparency in Order Status

Traditional Manufacturers tend to use legacy e-commerce solutions as their eCommerce portal for customers to create quick orders. As the order data gets captured in SAP quickly, legacy integration tools find it extremely hard to report on the current order status for the sales and service team who live in Salesforce CRM. This becomes more complicated for Manufacturers who have multiple levels of hierarchies on products and bills of materials for the orders that continue to reside in SAP. Due to complexities in product level and order level data, the current state of integration followed by Manufacturers involve batch integrations at regular intervals syncing Salesforce with SAP. However, with volatile supply chains and service teams facing extreme support requests from customers, this integration approach results in service teams reporting on outdated order requests leading to more angry and frustrated customers.

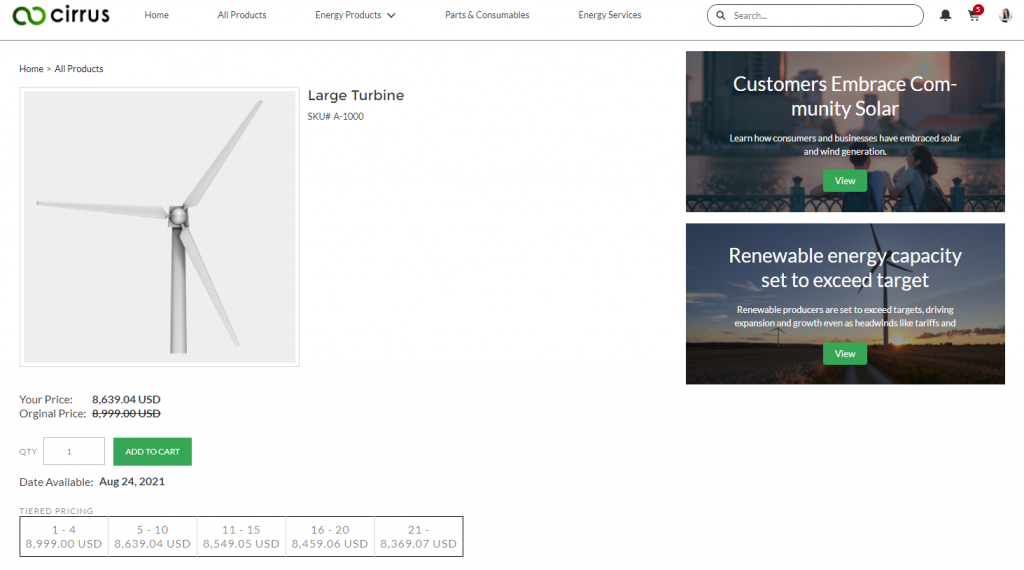

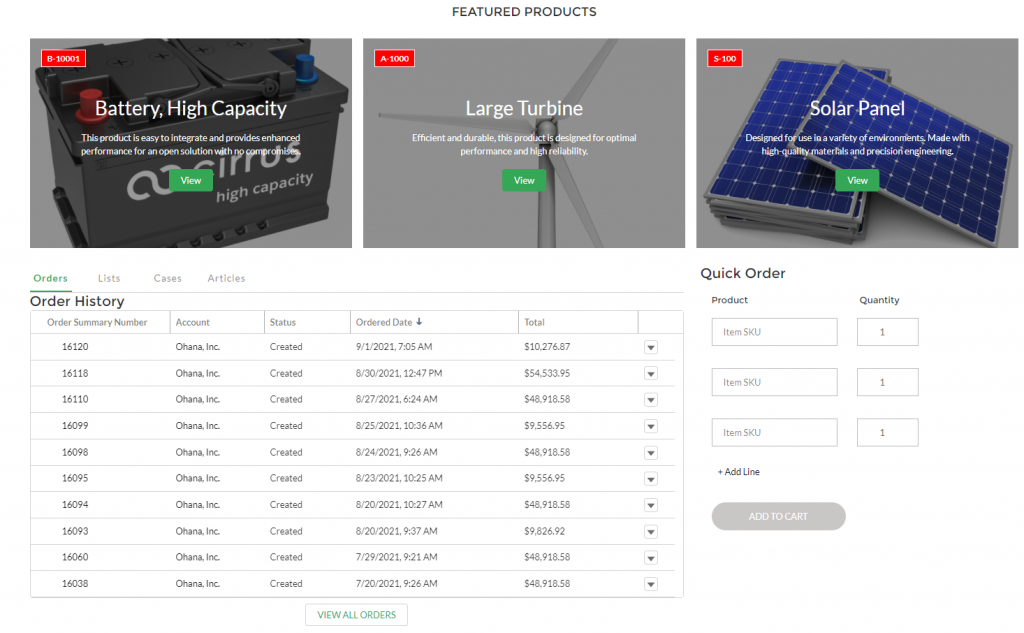

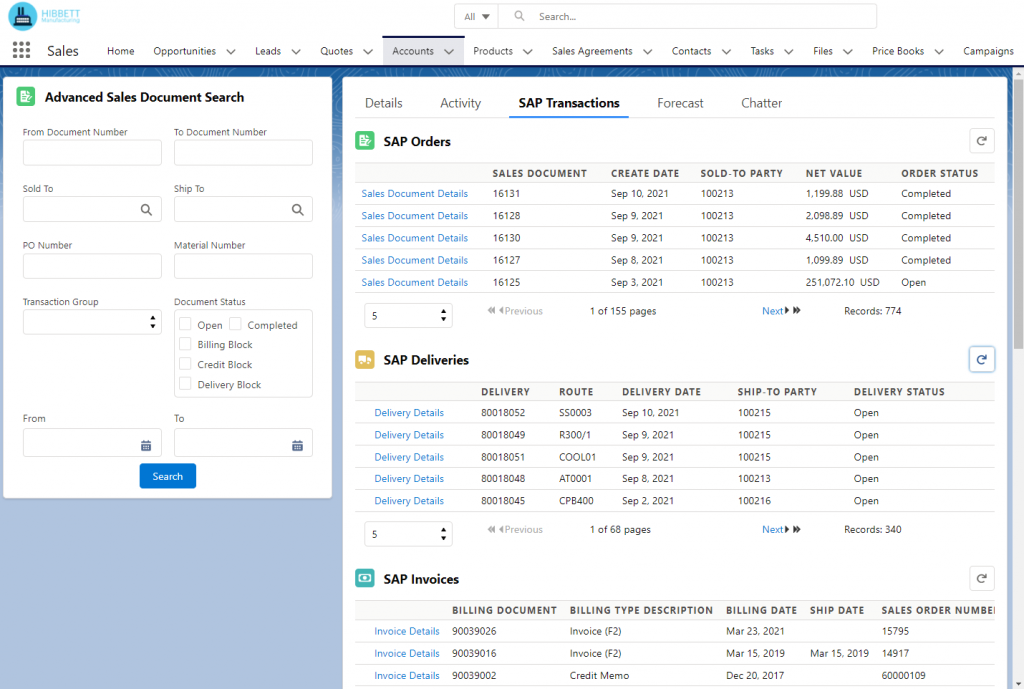

So as an IT/CRM leader, the need for real-time integration of Orders with your CRM is a must to resolve the issue. enosix with its real-time integration with SAP is a huge asset to resolve support issues. Leveraging enosix order integration capabilities, customers can quickly configure orders created in SAP to be posted in real-time in Salesforce using both standard order objects and custom objects as well. If the order is created leveraging Salesforce B2B commerce solution, it would be validated real-time with SAP and populated in SAP easily. The complexity involving product master hierarchies is completely abstracted by enosix using flattening techniques or controlled product hierarchy display solutions. The below screenshots explain how your sales and service teams can see all the order status in one screen leveraging Salesforce and SAP.

Real-time communication on order status with the right data at the right time is the key to winning customer confidence and trust. Instead of sending duplicate messages in 2 systems like SAP and Salesforce, leveraging enosix solutions, manufacturers can get all the order data in real-time in Salesforce and leverage Salesforce out-of-the-box email template features to inform customers on real-time order status. Marketing automation tools like the Marketing cloud can be used to create customer journeys that can send messages to customers on order status, delays, alternate measures taken by the Order teams in multiple channels using Email, Mobile, and Social Media. This can result in transparency in Order status winning customer trust which is critical during turbulent times.

So as a CRM leader during turbulent times, here are 2 simple strategies which you can have your team focus on resulting in increasing customer confidence and reducing frustrations.

1. Build control mechanisms with automation to flag pricing requests which deviate from standard pricing controls.

2. Bring transparency to orders with real time integration of SAP with Salesforce leveraging communication capabilities of salesforce to let customers know on order changes throughout the order life cycle resulting in increased trust.

As always feel free to email the author, Buyan Thyagarajan at buyan@eigenx.com with any questions or comments.